From System Model to Operational Environment: Testing H2-Hybrid Drives for Mobile Machinery

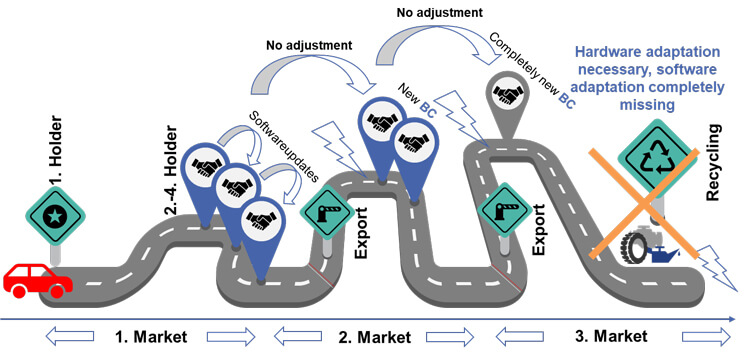

To date, mobile machinery has mostly been powered by combustion engines and contributes significantly to environmental impact in Germany [1]. Increasing environmental awareness is reflected in legislation aimed at making European mobile machinery the cleanest in the world [2]. Hybrid H2 drives with battery and fuel cell promise zero well-to-wheel emissions and therefore offer the potential to meet future climate targets. However, integrating hybrid H2 FC drives into mobile machinery presents a notable challenge due to the complex mechatronic nature of these systems.