Enhancing the electrification of existing commercial vehicle platforms by an innovative drive concept

Voith is revolutionizing the automotive sector's transition to sustainability with its cutting-edge Voith Electrical Drive System for heavy duty applications. As customers increasingly demand climate-neutral solutions for their existing platforms, the VEDS HD+ emerges as an innovation. Designed for heavy-duty trucks and special-purpose vehicles, this high-voltage drive system offers exceptional efficiency, extended vehicle range, and reduced emissions. With its modular design and compatibility, it is easily integrable into existing chassis, enabling a faster transition to zero-emission mobility.

System Overview

The VEDS HD+ offers several advantages over conventional drivetrains. It is remarkably quiet, has low energy consumption, and boasts high energy recuperation rates, resulting in extended vehicle range. The system is suitable for a range of commercial vehicle applications, including garbage collectors, heavy-duty trucks up to 44 tons, and special-purpose vehicles used in construction, mining, and agriculture. Importantly, Voith's solution is future-proof and can accommodate zero-emission vehicle technologies such as fuel cells or battery electric applications. It also simplifies the conversion of existing vehicle fleets, as it doesn't require additional installation space in the combustion engines' chassis. The layout of the VEDS HD+ is designed as a modular and scalable system, easy to apply even in existing platforms. The OEM has the full choice of configurations, and this gives him a significant increase in speed in the electrification of his portfolio.

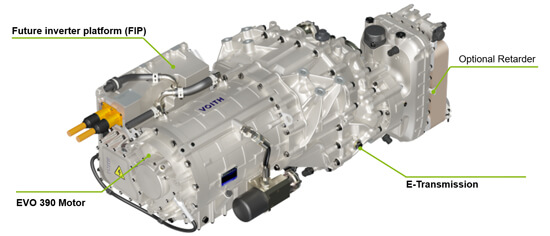

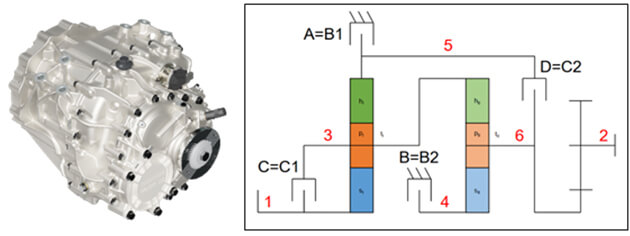

The VEDS HD+ is built on a modular design, consisting of three main components: the high-speed EVO motor, the Future Inverter Platform (FIP), and the E-Transmission. The EVO motor comes in two power categories, offering power levels ranging from 330 to 390 kW. The FIP provides flexibility with different voltage options (400 V or 800 V) and interfaces for water-cooling, high-voltage (HV) connection, and low-voltage (LV) connection. The Drive Management System (DMU) is also integrated into the drive unit. The VEDS HD+ features mechanical components like a 4-speed transmission and a hydrodynamic retarder as optional additions, making it suitable for heavy-duty vehicles that require efficient and high-power braking systems.

Motor

One of the highlights of the VEDS HD+ is its electric motors, the EVO 330 and EVO 390. These motors combine Voith's expertise in electric drive trains and motor design with their long-term experience in transmissions for commercial vehicles. The EVO motors offer a more compact design with higher speeds, requiring less copper and rare earth materials compared to traditional high-torque motors. This not only reduces costs but also contributes to sustainability. The motors can reach a maximum speed of 10,000 rpm and provide high-power density, making them ideal for electric vehicles.