Source: IPEK-Institute of Product Engineering at KIT

At IPEK sustainability is not only seen as a boundary condition, but as an opportunity for product differentiation on the market and as an important factor for future innovative product solutions.

The carcity of key raw materials and resources, combined with the rapid increase in world population, makes sustainability one of the most relevant issues in society, politics, business and science.

Justicing to the importance of sustainability, the IPEK-Institute of Product Engineering at KIT explicitly establishes the research field sustainability making a research contribution in this area. At IPEK sustainability is not only seen as a boundary condition, but as an opportunity for product differentiation on the market and as an important factor for future innovative product solutions.

Key research areas in this area are the operationalization of sustainability requirements and the inclusion of the circular economy in product development. IPEK esearches how companies can strategically align themselves with regard to short- and long-term sustainability goals having the aim to prioritize company-relevant sustainability requirements. Based on this, objectives are then defined and operationalized with the help of a roadmap for the transformation to a more sustainable company.

Furthermore, integrating the circular economy into the product creation process plays a crucial role in creating sustainable and resource-efficient products. The targeted design of products with a view to their later reuse and further use can make an important contribution to conserving natural resources.

Modular Product Architecture for easy Adaptability

One solution to achieve easy adaptability of the product over its lifetime within the IPeM can be modular product architectures. [6] The technical system consists of several components (subsystems) connected by as few standardized interfaces as possible.

Adjustable vehicle configurations can be achieved most easily with modular system architectures. Using the integrated product development model, an engineer will be able to develop products that can meet different needs during their use with an identical but modifiable basic structure. [7]

The modular design with standardized interfaces makes it possible to exchange subsystems of the powertrain and thus easily ensure functional performance under different boundary conditions. Modular hybridization also makes it possible to modify the powertrain and replace subsystems without much effort. Furthermore, because the reference product of an AMT is a manual transmission, the knowledge required by the mechanic is manageable.

The IPEK sees sustainability not only as a marginal condition, but as an opportunity for product differentiation on the market and as an important factor for future innovative product solutions.

The first key research areas in this area are the operationalization of sustainability requirements and the integration of the circular economy in product development. These form the basis for links to other relevant research projects at IPEK and KIT.

This work within IPEK issues sustainability regarded in product development taking the automotive industry as an example of research. The results of this work can easily be transferred to general product development.

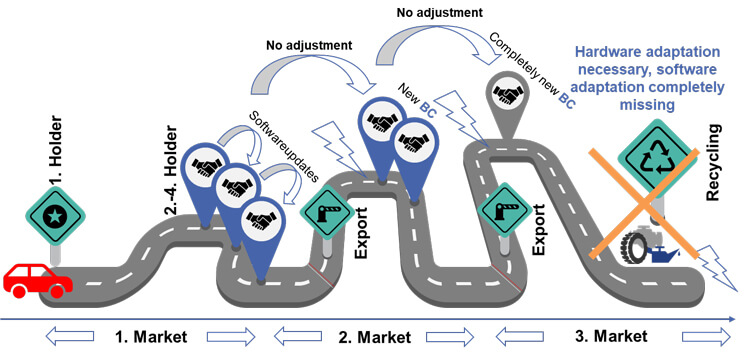

A vehicle, adapted to the initial customer with a high comfort level and complicated technical systems, is susceptible to faults due to up to 30 years of use. As can be seen in the figure, vehicles enter different markets being exported to faraway places like Africa after the end of their service life in the initial market. In Africa they are often kept ready for operation instead of being correctly scrapped. The cars at this point are incorrectly scrapped because defective parts are no longer relevant for meeting the market-specific requirements. The technical infrastructure in these faraway markets is superficial and inadequate for servicing and maintaining vehicles. A car that could still be used for a longer time is nevertheless taken out of service for this reason, often improperly.

We use adequate methods of KaSPro - Karlsruhe School for Product Development - to make new vehicles more adaptable to different markets by adapting the development process.

Requirements for the Development of a more Adaptable Vehicle over life-time and Markets

In future, the developers should thereby be supported in their work to fulfill the needs of further sales areas in addition to focusing on the requirements of the initial costumer. In order to establish these adaptation possibilities successfully, the user behavior and demands of the different markets must be analyzed and described first using methods such as forecasting. In the development process, a product architecture adapted to the other markets can then be developed with the help of KaSPro methods.

Design of Adaptable Product Architectures based on KaSPro Methods

To design vehicles adaptable to different markets, the characteristics of integrated product engineering are interesting.

The Integrated Product Engineering Model (IPeM) forms a reference model for Systems Generation Engineering (SGE), according to ALBERS [1] using the problem-solving method SPALTEN [2, 3]. The model of the SGE describes the basic idea that products are developed over generations. According to ALBERS, the starting point for the development of the current product generation is always a reference system, which contains of elements likereference products or objects and objectives of previous products. They provide a basic structure on which the new product is built.

As part of the system of objectives in IPeM, requirements must first be recorded in the form of a future forecast. For this purpose, the foresight results are usable in a systematic design for setting up an initial system of objectives in the early phase of system generation development. This includes forecasts, trends, and scenarios. In the area of adaptable systems, trends for the medium term must be determined, and scenarios for longer-term statements must be used to find suitable interfaces and basic architectures [4, 5].

Adapting the product architecture to various markets in this way leads to the product’s sustainability expanding its lifetime by preveting its premature scrapping in the market it is later based in.

We aim to support the designof a sustainable system architecture for products adaptable across multiple customer and user groups. Modular product architectures can be systematically designed in different variants, which are versioned over time via updates.

For this purpose, the integrated product engineering model (IPeM) and system generation engineering (SGE), according to ALBERS, were used.

Thus, drivetrains, for example, can provide more excellent value to many people in different regions through adaptation while contributing to environmental protection and increased sustainability through, for example, reductions in inputs and module upgrades. They thereby contribute to a sustainable mobility.

References

[1] Albers, Albert; Kürten, Claas; Rapp, Simon; Birk, Clemens; Hünemeyer, Sebastian; Kempf, Christoph (2022): SGE - Systemgenerationsentwicklung. Analyse und Zusammenhänge von Entwicklungspfaden in der Produktentstehung (KIT Scientific Working Papers, 199). Online available about publikationen.bibliothek.kit.edu/1000151151.

[2] M. Saak, „Development of a concept and of a prototype for a computer-aided tool for the efficient employment of the problem solving methodology “SPALTEN“, 2006.

[3] A. Albers, N. Reiss, N. Bursac und T. Richter, „iPeM – Integrated Product Engineering Model in Context of Product Generation Engineering“, Procedia CIRP, Jg. 50, S. 100–105, 2016, doi: 10.1016/j.procir.2016.04.168.

[4] A. Fink und A. Siebe, Handbuch Zukunftsmanagement: Werkzeuge der strategischen Planung und Früherkennung, 2. Aufl. Frankfurt am Main: Campus Verlag GmbH, 2011. [Online].

[5] J. Gausemeier et al., „Strategische Produktplanung: adaptierbare Methoden, Prozesse und IT-Werkzeuge für die Planung der Marktleistungen von morgen“ (de), Strategische Produktplanung, doi: 10.2314/GBV:870185012.

[6] M. Buchmüller, „Nachhaltigkeit und Produktmodularisierung“. Dissertation, Springer Fachmedien Wiesbaden.

[7] K. Ehrlenspiel und H. Meerkamm, Integrierte Produktentwicklung: Denkabläufe, Methodeneinsatz, Zusammenarbeit, 5. Aufl. München: Hanser, 2013.

Authors

M.Sc. Bastian Glasmacher, Institute of Product Engineering, Karlsruhe, Germany

M.Sc. Moritz Seidler, Institute of Product Engineering, Karlsruhe, Germany

Dipl.-Ing. Katharina Bause, Institute of Product Engineering, Karlsruhe, Germany

M.Sc. Rüdiger Fehrenbacher, Institute of Product Engineering, Karlsruhe, Germany

M.Sc. Felix Pfaff, Institute of Product Engineering, Karlsruhe, Germany

Univ.-Prof. Dr.-Ing. Dr. h. c. Albert Albers, Institute of Product Engineering, Karlsruhe, Germany

Dipl. Ing Sascha Ott, IPEK - Institute of Product Engineering, Karlsruhe, Germany